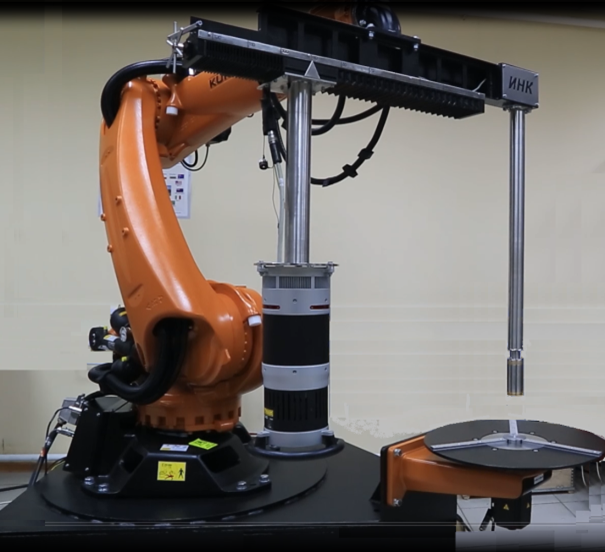

The system is designed for radiation monitoring of weld seams of rotors of gas turbine engines, cylindrical thin-walled casings and small-sized castings.

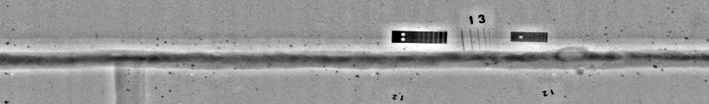

The system receives a digital image of the monitoring object on the line of X-ray detectors during scanning in the fan beam of the X-ray source and carries out its processing, analysis and archiving.

Developed together with the Department of Physical Methods of Non-Destructive Testing TPU.

| Characteristics of a spiral tomograph: | |

| Name | Value |

| Maximum dimensions of the controlled sample (diameter, height), mm | 700×1000 |

| Minimum dimensions of the controlled sample (diameter, height), mm | 200×150 |

| Maximum mass of the sample to be monitored, kg | 200 |

| The minimum step of the angular displacement of the object, deg | 0,001 |

| Measured metal thickness (in steel), mm | 2% |

| Spatial resolution (line pairs per mm) | 5 |

| Overall dimensions of the system (width, depth, height), mm | 2000×1400×2000 |

| Anode voltage, kV | up 450 |

| Weight (kg), no more than: | 2000 |

| The supply voltage of the complexes from the alternating current network, V | 380±10% |

| Detector size | 2048х2048 |

| Power consumed by the complex from the alternating current network, kW, not more than: | 15 |

| MTBF, h, not less than | 6000 |

| Average service life, years | 10 |